When it comes to heavy lifting, having the right equipment can make all the difference between a smooth operation and a potential disaster. One indispensable piece of equipment that stands out is the lifting block tripod. Whether you are in construction, engineering, or any field requiring the lifting of heavy objects, understanding the benefits, applications, and proper use of a lifting block tripod is essential. In this comprehensive guide, we’ll delve into everything you need to know about this vital tool.

What is a Lifting Block Tripod?

GET IT NOW

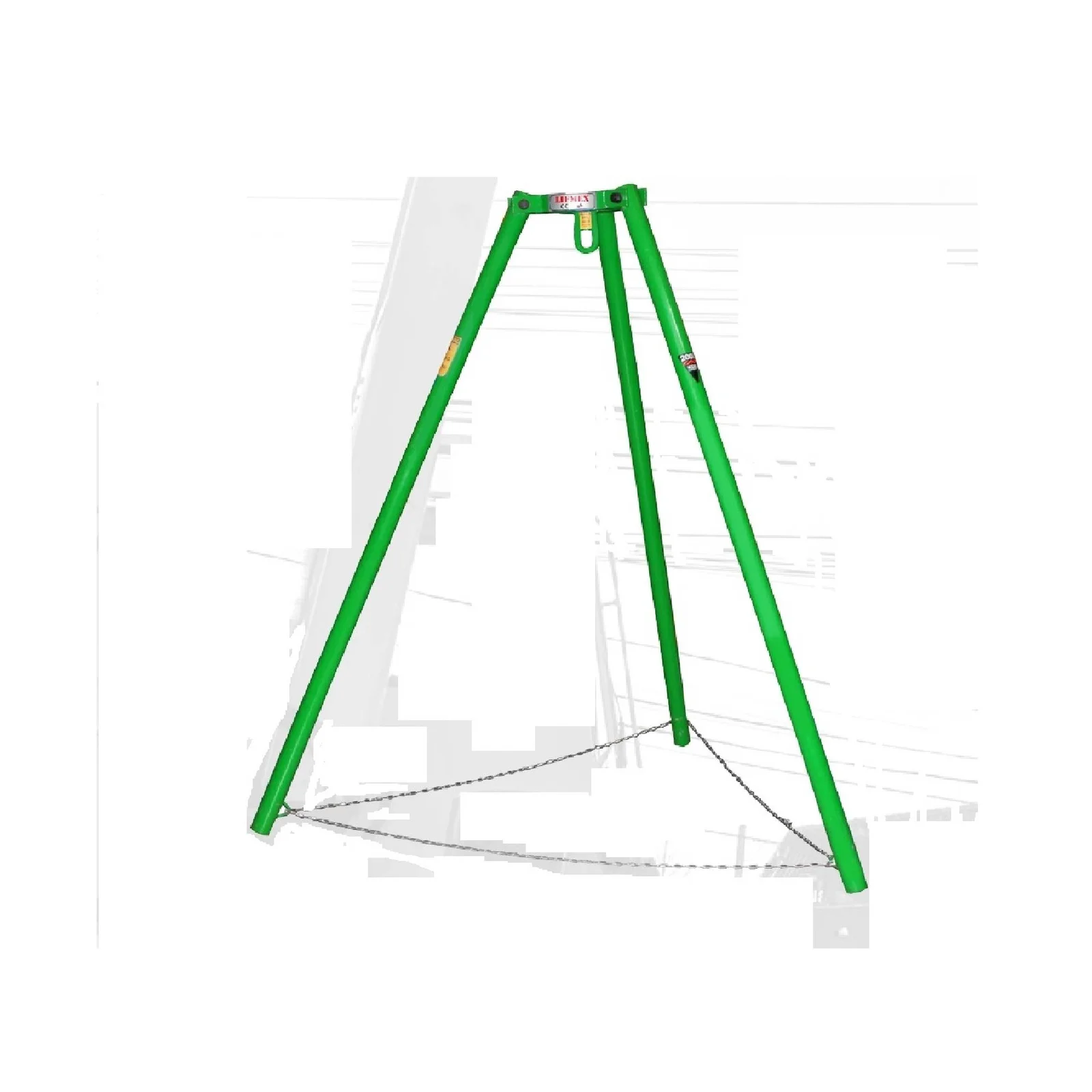

A lifting block tripod is a three-legged structure designed to support lifting operations, typically constructed from high-strength materials like steel or aluminum. Its design ensures superior stability and even weight distribution, making it a reliable choice for lifting heavy loads safely and efficiently.

Key Features of a Lifting Block Tripod

- Stability: The tripod’s three-legged configuration provides unmatched stability compared to other lifting devices. Each leg can be individually adjusted, allowing for secure setup even on uneven terrain.

- Portability: Despite their robust construction, lifting block tripods are designed to be lightweight and easy to transport. This portability makes them suitable for various environments, whether on a construction site or in a workshop.

- Versatility: A lifting block tripod can be used to lift a wide array of objects, from heavy machinery and construction materials to rescue operations where quick and secure lifting is essential.

Advantages of Using a Lifting Block Tripod

Enhanced Safety

Safety is paramount when dealing with heavy lifting. The lifting block tripod significantly enhances safety by providing a stable platform for lifting operations. The tripod’s design ensures that the load is evenly distributed, reducing the risk of tipping or collapsing. Moreover, the ability to adjust each leg individually allows for a secure setup on uneven surfaces, further minimizing the risk of accidents.

Increased Efficiency

Lifting block tripods are highly efficient, saving time and effort during lifting operations. Their quick setup process allows workers to focus on other tasks, increasing overall productivity. Once in place, a tripod can handle multiple lifts without needing constant adjustments, making it an invaluable tool for continuous operations.

Versatile Applications

Lifting block tripods are used across various industries, showcasing their versatility:

- Construction: Ideal for lifting beams, concrete blocks, and other heavy construction materials.

- Engineering: Perfect for hoisting machinery and equipment in engineering projects.

- Rescue Operations: Essential for lifting and securing objects during emergency situations, such as natural disasters.

Choosing the Right Lifting Block Tripod

Selecting the appropriate lifting block tripod for your needs involves considering several factors:

- Load Capacity: The tripod must be able to handle the weight of the objects you need to lift. Exceeding the load capacity can lead to tripod failure and potential accidents.

- Material: Tripods made from durable materials like steel or aluminum offer the best combination of strength and portability. Steel provides superior strength, while aluminum offers a lighter, more portable option.

- Height Adjustability: Ensure the tripod has adjustable legs to accommodate different lifting heights. This flexibility is crucial for various tasks and environments, allowing for precise control over the lifting process.

Proper Use and Safety Guidelines

To ensure safe operation of a lifting block tripod, adhere to the following guidelines:

Inspect Before Use

Always inspect the tripod before use. Check for any signs of damage or wear, such as cracks, bends, or other defects that could compromise its integrity. Regular inspections help identify potential issues before they become serious problems.

Secure Setup

Set up the tripod on a stable surface, ensuring all legs are securely locked in place. This prevents the tripod from tipping over during lifting operations. On uneven surfaces, adjust the legs individually to maintain stability.

Adhere to Load Limits

Never exceed the manufacturer’s recommended load capacity. Overloading the tripod can cause it to fail, leading to serious accidents and potential injuries. Always check the load capacity and ensure it matches the weight of the objects being lifted.

Use Proper Accessories

Use appropriate slings, chains, or hooks to attach the load to the tripod. Ensure that all connections are secure and properly rated for the weight being lifted. Using the correct accessories is crucial for maintaining safety and efficiency during lifting operations.

Detailed Applications of Lifting Block Tripods

Construction Industry

In the construction industry, the efficient and safe movement of heavy materials is a daily necessity. Lifting block tripods play a critical role in ensuring that these tasks are performed with precision and safety. Their design and functionality make them particularly well-suited for the demanding and often unpredictable environments of construction sites.

Stability and Safety

One of the primary reasons lifting block tripods are invaluable in construction is their exceptional stability. Construction sites are typically characterized by uneven ground, debris, and varying terrain. A lifting block tripod, with its three-legged design, provides a stable and secure platform for lifting operations. Each leg can be adjusted independently, allowing the tripod to be set up on uneven surfaces without compromising its stability. This flexibility is crucial for maintaining safety, as an unstable lifting platform can lead to accidents, injuries, or damage to materials.

Ease of Setup and Portability

Construction projects often require the movement and lifting of materials across different parts of a site. Lifting block tripods are designed for ease of setup and portability, making them ideal for such dynamic environments. The ability to quickly assemble and disassemble the tripod means that it can be relocated as needed, without significant downtime. This portability ensures that lifting operations can continue smoothly and efficiently, regardless of where they are needed on the site.

Versatility in Lifting Operations

Lifting block tripods are incredibly versatile, capable of handling a wide range of materials and components commonly used in construction. For example:

- Steel Beams: These are essential structural elements in many construction projects. The tripod’s strength and stability allow for the safe lifting and positioning of steel beams, ensuring they can be accurately placed without risk of tipping or instability.

- Concrete Blocks: Heavy and cumbersome, concrete blocks require reliable lifting equipment. A lifting block tripod can securely lift and hold these blocks, facilitating their placement in walls, foundations, or other structures.

- Machinery and Equipment: Construction sites often involve the use of heavy machinery and equipment. Whether it’s for installation, maintenance, or relocation, a lifting block tripod can provide the necessary support to lift and maneuver these items safely.

Enhancing Efficiency and Productivity

By ensuring safe and stable lifting operations, lifting block tripods enhance overall efficiency and productivity on construction sites. Workers can focus on their tasks without the constant worry of equipment failure or accidents. The quick setup and adaptability of the tripod mean that lifting operations can be integrated seamlessly into the workflow, reducing delays and keeping projects on schedule.

Real-World Application

Consider a scenario where a construction team needs to install a large steel beam as part of a building’s framework. The beam is too heavy to be lifted manually and needs to be positioned with precision. A lifting block tripod is set up on the site, with each leg adjusted to ensure stability on the uneven ground. Using a chain block or a similar lifting mechanism attached to the tripod, the team lifts the beam into place. The tripod holds the beam securely, allowing workers to position it accurately and safely fasten it to the structure.

In another example, a team working on a high-rise building might need to move heavy concrete blocks to different floors. A portable lifting block tripod can be set up quickly, moved between floors as needed, and used to lift the blocks safely, ensuring that the construction process remains efficient and uninterrupted.

Engineering Projects

In the realm of engineering projects, the precise movement and installation of heavy machinery and equipment are critical tasks. Lifting block tripods are indispensable tools in these settings, providing the necessary stability, control, and safety to ensure that these operations are carried out efficiently and accurately. Here’s an in-depth look at why lifting block tripods are vital in engineering projects.

Stability and Control

Engineering projects often require the handling of complex and heavy machinery that must be lifted, moved, and positioned with exact precision. A lifting block tripod offers unparalleled stability due to its three-legged design, which distributes weight evenly and reduces the risk of tipping. Each leg is independently adjustable, allowing for secure setups even on uneven surfaces commonly found in engineering environments. This stability is crucial when working with expensive and sensitive machinery, as even minor shifts can lead to significant damage or misalignment.

Precision in Lifting and Positioning

Precision is key in engineering projects, whether it’s installing a new piece of machinery or maintaining existing equipment. Lifting block tripods allow for precise control over the lifting process. The ability to make fine adjustments ensures that machinery can be positioned exactly where it is needed. This level of control is particularly important in scenarios such as:

- Machinery Installation: When installing machinery, precise alignment is essential for optimal performance. A lifting block tripod can hold the equipment steady, allowing engineers to make necessary adjustments without the risk of movement.

- Equipment Maintenance: During maintenance, lifting block tripods provide a secure way to access different parts of the machinery. The stability of the tripod ensures that the equipment remains in place, facilitating safe and efficient maintenance operations.

Versatility for Various Applications

Lifting block tripods are versatile tools that can be used in a wide range of engineering applications. Their adaptability makes them suitable for different types of lifting tasks, including:

- Heavy Machinery: Whether it’s a large generator, motor, or industrial press, lifting block tripods can handle substantial weights, providing a reliable lifting solution.

- Delicate Equipment: For more sensitive equipment, such as precision instruments or electronic components, the controlled lifting environment provided by a tripod minimizes the risk of damage.

- Modular Components: Engineering projects often involve assembling modular components. Lifting block tripods can assist in aligning and securing these components accurately.

Enhancing Safety and Efficiency

Safety is a paramount concern in engineering projects. The robust design of lifting block tripods minimizes the risk of accidents during lifting operations. By securely holding heavy and potentially hazardous machinery, tripods help prevent injuries that can occur from dropping or mishandling equipment. This focus on safety also enhances overall project efficiency, as workers can perform their tasks with confidence, knowing that the lifting apparatus is reliable and secure.

Real-World Applications

Consider a scenario where an engineering team needs to install a new industrial pump in a factory. The pump is heavy and must be positioned precisely to connect with existing infrastructure. A lifting block tripod is set up, with its legs adjusted for stability on the factory floor. Using a chain hoist attached to the tripod, the team lifts the pump and maneuvers it into place. The tripod holds the pump steady, allowing for precise alignment with the connecting pipes and fittings. Once the pump is correctly positioned, the team can secure it, confident that the installation is accurate and stable.

In another example, an engineering team is tasked with maintaining a large piece of machinery in a power plant. The machinery needs to be lifted to access certain components for inspection and repair. A lifting block tripod provides a safe and stable platform for this task, allowing the team to lift the machinery and perform maintenance without risk of it shifting or falling.

Rescue Operations

In emergency situations, such as natural disasters, the ability to quickly and securely lift heavy objects can mean the difference between life and death. Lifting block tripods are essential tools in rescue operations, providing the stability, portability, and ease of setup required to effectively lift debris, secure unstable structures, and extract trapped individuals. Here’s a detailed look at why lifting block tripods are indispensable in rescue scenarios.

Quick and Secure Lifting

During rescue operations, time is of the essence. The rapid deployment and secure lifting capabilities of lifting block tripods are crucial. These tripods can be quickly assembled and positioned, allowing rescue teams to immediately start lifting debris and other obstacles that may be trapping individuals. The robust design of the tripod ensures that the load is securely held, minimizing the risk of further injury or collapse during the rescue process.

Stability in Unstable Environments

Natural disasters often leave behind unstable environments with uneven terrain, collapsed structures, and loose debris. Lifting block tripods provide the necessary stability to operate safely in such conditions. Their three-legged design ensures that weight is evenly distributed, preventing tipping and ensuring a stable lifting platform. This stability is vital when working in precarious situations where additional movement or shifting could cause further harm.

Portability and Ease of Setup

Rescue operations require equipment that is both portable and easy to set up. Lifting block tripods meet these requirements perfectly. Their lightweight yet sturdy construction makes them easy to transport to the rescue site, whether by vehicle or on foot. Once on-site, the tripods can be quickly assembled and adjusted to suit the specific needs of the rescue operation. This quick setup allows rescue teams to respond rapidly, increasing the chances of successful rescues.

Versatility in Rescue Scenarios

Lifting block tripods are highly versatile and can be used in various aspects of rescue operations:

- Lifting Debris: One of the primary uses of lifting block tripods in rescue scenarios is lifting heavy debris that may be trapping individuals. Whether it’s large chunks of concrete, fallen beams, or other heavy materials, the tripod can securely lift and hold these objects, allowing rescuers to reach and free trapped individuals.

- Securing Unstable Structures: In the aftermath of a disaster, many structures may be left unstable and at risk of further collapse. Lifting block tripods can be used to stabilize these structures, preventing additional harm and creating safe pathways for rescue teams to operate.

- Extraction of Trapped Individuals: In some cases, individuals may be trapped in confined spaces or under heavy objects. Lifting block tripods provide a controlled and stable method to lift and extract these individuals safely. The precision and control offered by the tripod are essential to avoid causing further injury during the extraction process.

Enhancing Rescue Efficiency and Safety

The use of lifting block tripods enhances both the efficiency and safety of rescue operations. By providing a reliable lifting mechanism, tripods allow rescue teams to focus on their primary task—saving lives—without worrying about the stability or security of their equipment. This reliability not only speeds up the rescue process but also reduces the risk of additional injuries to both the trapped individuals and the rescuers.

Real-World Applications

Imagine a scenario where a natural disaster, such as an earthquake, has caused a building to collapse, trapping people under the rubble. A rescue team arrives at the scene with lifting block tripods. They quickly set up a tripod near a large piece of concrete debris. Using a chain hoist attached to the tripod, they lift the debris to create an opening. The stability of the tripod ensures that the debris is securely held in place, allowing rescuers to reach and safely extract the trapped individuals.

In another example, during a hurricane, a house partially collapses, leaving individuals trapped inside. The rescue team uses a lifting block tripod to stabilize the structure and prevent further collapse while they work to rescue the trapped individuals. The tripod’s portability allows it to be quickly moved and set up in various locations around the house as needed, ensuring the safety of both the rescuers and those trapped inside.

Industrial Maintenance

In industrial settings, maintenance tasks often involve lifting and moving heavy equipment. Lifting block tripods are invaluable tools in these scenarios, providing the necessary stability, strength, and versatility to ensure that equipment can be safely lifted and serviced. Whether it’s routine maintenance or emergency repairs, lifting block tripods play a crucial role in maintaining the efficiency and safety of industrial operations. Here’s a detailed look at how lifting block tripods are used in industrial maintenance.

Stability and Strength for Heavy Lifting

Industrial maintenance frequently requires the handling of large, heavy machinery and equipment. Lifting block tripods offer the stability and strength needed to safely lift these heavy loads. The tripod’s three-legged design ensures even weight distribution, reducing the risk of tipping or collapsing. This stability is particularly important when working with complex and sensitive equipment, where even minor shifts can lead to damage or misalignment.

Versatility in Maintenance Operations

Lifting block tripods are highly versatile and can be used in various maintenance tasks:

- Routine Maintenance: Regular maintenance of industrial equipment often involves lifting parts for inspection, cleaning, and servicing. A lifting block tripod provides a stable platform to safely lift and hold these parts, allowing maintenance teams to perform their tasks efficiently and effectively.

- Emergency Repairs: In case of equipment failure or breakdown, quick and safe lifting is crucial to perform emergency repairs. Lifting block tripods enable maintenance teams to lift heavy machinery and components, providing access to damaged parts and facilitating prompt repairs.

- Installation and Replacement: When installing new equipment or replacing old machinery, lifting block tripods offer a reliable method to lift and position heavy components accurately. This precision is essential for ensuring proper installation and alignment.

Enhancing Safety in Maintenance Tasks

Safety is a top priority in industrial maintenance. The robust construction and stability of lifting block tripods help minimize the risk of accidents during lifting operations. By securely holding heavy equipment in place, tripods prevent unexpected shifts or falls that could cause injury to workers or damage to machinery. This focus on safety also enhances overall productivity, as workers can perform their tasks with confidence, knowing that their lifting equipment is reliable.

Efficiency and Productivity

Lifting block tripods contribute to the efficiency and productivity of maintenance operations in several ways:

- Quick Setup and Operation: The ease of setup and operation of lifting block tripods means that maintenance teams can quickly begin lifting tasks without significant downtime. This quick deployment is particularly valuable during emergency repairs, where time is of the essence.

- Minimal Downtime: By providing a stable and efficient lifting solution, lifting block tripods help minimize equipment downtime. This ensures that maintenance tasks are completed swiftly, allowing production processes to resume with minimal disruption.

- Portability: Lifting block tripods are designed to be portable, making it easy to move them between different locations within an industrial facility. This portability ensures that maintenance teams have the flexibility to address lifting needs wherever they arise.

Real-World Applications

Consider a scenario where an industrial plant needs to perform routine maintenance on a large conveyor system. The conveyor’s motor, which is heavy and difficult to access, needs to be lifted for inspection and servicing. A lifting block tripod is set up near the conveyor, with its legs adjusted to ensure stability on the plant floor. Using a chain hoist attached to the tripod, the maintenance team lifts the motor, providing clear access for inspection and servicing. The tripod’s stability ensures that the motor remains securely held in place throughout the maintenance process.

In another example, an industrial facility experiences a sudden breakdown of a crucial piece of machinery. The maintenance team must quickly lift a heavy gearbox in order to access and repair a damaged component. A lifting block tripod is quickly deployed, allowing the team to lift the gearbox safely and efficiently. Moreover, the tripod’s robust construction and stability provide a secure lifting platform, enabling the team to perform the necessary repairs and, consequently, minimize production downtime.

Conclusion

A lifting block tripod is an essential tool for anyone involved in heavy lifting operations. Its stability, portability, and versatility make it an invaluable asset across various industries. By choosing the right tripod and following safety guidelines, you can ensure efficient and safe lifting operations. Whether you are in construction, engineering, or rescue operations, a lifting block tripod can significantly enhance your lifting capabilities. Investing in a lifting block tripod is not just about improving efficiency; it’s about ensuring safety and reliability in every lifting task you undertake. So, next time you face a heavy lifting challenge, consider the benefits of a lifting block tripod – it might just be the best decision you make for your project.