If you are looking for information or advice on hoists, our comprehensive guide can assist you. It covers the different types of hoists, their uses, factors to consider, and features to look for.

What are Hoists?

A hoist is a device that lifts and holds objects by using mechanical advantage. It uses pulleys or gears to change low force over long distances into high force over short distances. It has a chain or rope that wraps around a drum or wheel and then around other pulleys or gears with different sizes, some of which may be in the load block. The arrangement, affecting how the load’s force is shared or moved, is called the reeving. Hoists, whether fixed or mobile, can lift things for general or specific purposes, such as extracting a car engine. Hoists usually have a hook at the fixed end that attaches to a crane or trolley and a hook at the moveable end that grabs the load.

Types of Hoists Shabbir Enterprises Offer You

Hoists can be classified into different types based on their lifting mechanism, power source, and suspension method. , we are introducing you to the 8 types of hoists that Shabbir Enterprises offers:

Electric Chain Hoist Hook

GET IT NOW

An electric chain hoist hook is a type of hoist that uses an electric motor to drive a chain that lifts or lowers the load. The hook is attached to the end of the chain and can be easily hooked or unhooked to the load.

Electric chain hoist hooks are suitable for lifting light to medium loads up to 5 tons. They are easy to operate, reliable, and low-maintenance. They can be used in workshops, warehouses, factories, and other places where electricity is available.

Electric Chain Hoist with Electric Trolley

GET IT NOW

An electric chain hoist with electric trolley is similar to an electric chain hoist hook, except that it has an electric trolley that can move the hoist along a beam or rail. This allows the hoist to cover a larger area and transport the load horizontally as well as vertically.

Electric chain hoist with electric trolley can lift loads up to 10 tons and are ideal for applications that require frequent and precise positioning of the load. They can be used in assembly lines, production plants, shipyards, and other places where high efficiency and accuracy are required.

Electric Wire Rope Hoist

GET IT NOW

An electric wire rope hoist is a type of hoist that uses an electric motor to drive a wire rope that lifts or lowers the load. The wire rope is more flexible and durable than the chain and can handle heavier loads up to 20 tons.

Electric wire rope hoists, faster and smoother than electric chain hoists, offer customization to suit various lifting heights and speeds. Industries utilize them in cranes, bridges, gantries, and other settings where high performance and safety requirements exist.

Explosion Proof Chain Block

GET IT NOW

An explosion proof chain block is a type of manual hoist that uses a hand chain to operate a chain that lifts or lowers the load. Specially designed to prevent sparks, flames, or heat from igniting flammable or explosive gases or dust in the environment, the chain block ensures safety.

Explosion proof chain blocks can lift loads up to 50 tons and are suitable for hazardous areas, such as oil refineries, chemical plants, mines, and other places where fire or explosion risks are present.

Lever Hoist

GET IT NOW

A lever hoist is a type of manual hoist that uses a lever to operate a chain that lifts or lowers the load. The lever hoist is easy to use and can lift loads in any direction, including horizontally.

Lever hoists can lift loads up to 9 tons and are ideal for pulling, stretching, or positioning loads in tight spaces. They can be used in rigging, pipe fitting, cable installation, and other places where versatility and portability are required.

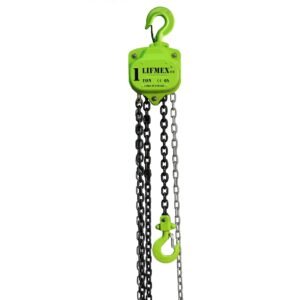

Manual Chain Block

GET IT NOW

A manual chain block is a type of manual hoist that uses a hand chain to operate a chain that lifts or lowers the load. The manual chain block is simple and economical and can lift loads up to 20 tons.

Workshops, garages, farms, and other locations where electricity is not available or necessary can use them.

Mini Wire Rope Hoist

GET IT NOW

A mini wire rope hoist is a type of electric hoist that uses a small electric motor to drive a wire rope that lifts or lowers the load. The mini wire rope hoist is compact and lightweight and can lift loads up to 1 ton.

They can be used in homes, offices, shops, and other places where space is limited and light lifting is needed.

Shop Crane Engine Hoist

GET IT NOW

A shop crane engine hoist is a type of hydraulic hoist that uses a hydraulic cylinder to lift or lower the load. The shop crane engine hoist is mounted on a wheeled frame that can be moved around the shop floor.

The shop crane engine hoist can lift loads up to 2 tons and are designed for lifting and moving engines, transmissions, and other heavy parts in auto repair shops

Hoists are essential tools that can make your lifting tasks easier, faster, and safer. Shabbir Enterprises offers a wide range of hoist types to suit your specific needs and preferences. Whether you need an electric, manual, or hydraulic hoist, we have the right solution for you.

Applications and Industries

Hoists are versatile devices that can lift and move loads in various settings, not only in industrial ones. Hoists can handle different types of loads, such as cargo, construction materials, engines, and warehouse stock.

Some of the industries that use hoists are:

- Aerospace

- Automotive

- Construction

- Logging

- Marine

- Manufacturing

- Medical

- Mining

Considerations

Operating time, frequency of usage, and load all factor into the life of the hoist. These factors as well as travel distance and speed will also affect the lifetime of the trolley, where applicable. Using equipment above recommended parameters will lower the product lifetime.

Operating time

Frequency of usage, and load. These factors affect the durability and performance of the hoist and the trolley (if applicable). To extend the product lifetime, you should follow the manufacturer’s recommendations and avoid overloading or overusing the hoist.

Operator’s effort

Manual hoists (lever or hand-operated) require physical effort from the operator to lift or lower the load. You should choose a manual hoist that is easy and comfortable to operate and does not exceed the operator’s limits.

Structure’s capacity

The hoist should be compatible with the structure that will support it, such as a beam, rail, or crane. You should check the weight capacity of the structure and make sure that the hoist and the load do not exceed it.

Application’s requirements

Depending on the type and frequency of lifting you need, you may prefer a motorized or a manual trolley. A motorized trolley can move the hoist and the load along the structure faster and more accurately than a manual trolley. A motorized trolley is recommended for applications that require regular lifting of 2 tons or more.

Load’s characteristics

The load’s weight, size, shape, and material may affect the type of hoist and accessories you need. For example, some loads may require a special load block or hook to secure them. You should consider the load’s characteristics when assessing your lifting needs and choosing the right hoist and accessories.

Hoist’s features

Some hoists may have special or custom features that suit your specific needs. For example, some hoists may be explosion-proof, corrosion-resistant, or low-noise. You should consult with the manufacturer or supplier to find out what hoist features are available and how they can benefit you.

New vs. Used Hoists

- Inspect the hoist rigging equipment. Look for any signs of wear and tear, such as cracks, rust, corrosion, or deformation. Replace any damaged or worn-out parts as soon as possible.

- Perform regular maintenance on the hoist. Follow the manufacturer’s instructions and schedule for cleaning, lubricating, and adjusting the hoist. This will help extend the hoist’s lifespan and prevent breakdowns.

- Obtain the serial number of the used hoist. This will help you find out the hoist’s specifications and limitations, such as its lifting capacity, speed, and height. You can also use the serial number to contact the manufacturer or supplier for any questions or issues.

- Be aware of the safety regulations for overhead cranes.

Important Attributes

Lift capacity

This is the maximum weight that the hoist can support. It depends on the strength of the chain or rope, the frequency of use, the power source, and the structure that supports the hoist. You should choose a hoist that has a higher lift capacity than your heaviest load.

Line material

This is the material that the chain or rope is made of. The most common line materials are chain and wire rope or cable. They are suitable for lifting heavy loads. For lighter loads, you can use rope and strap or webbing. They are more flexible and easy to handle.

Power source

This is the source of energy that drives the hoist. The simplest hoists are manual, operated by hand chains or levers. They are cheap and portable, but require physical effort. Electric hoists are the most common, powered by electricity. They are fast and reliable, but need a power supply. Portable hoists can be powered by fuel, such as gasoline or diesel. They are convenient and versatile, but noisy and polluting. Air and hydraulic hoists are powered by compressed air or fluid. They are safe and durable, but expensive and complex.

Suspension type

This is the way the hoist is attached to the structure. Some hoists are fixed, hooked or bolted to permanent fixtures or movable stands. They are stable and secure, but limited in range. Some hoists are movable, attached to overhead trolleys. They can be pushed or pulled along a rail or have a motorized unit. They are flexible and efficient, but need a track or beam.

Lift height

This is the distance between the highest and lowest positions of the load hook. The higher the lift height, the more space the hoist needs. The lift height and the headroom are the two components of the reach, which is the total height that the hoist can cover.

Lift speed

This is the speed at which the hoist can lift or lower the load. The faster the lift speed, the more productive the hoist is. The lift speed can vary depending on the load weight and height. Higher capacity hoists usually have lower lift speeds. Some hoists have multiple or variable speeds, which can adapt to different loads and situations.

Headroom

This is the distance between the rail or tread where the hoist sits and the load hook. The lower the headroom, the more compact the hoist is. The headroom and the lift height are the two components of the reach, which is the total height that the hoist can cover. Before choosing a hoist, you should know how and where you will use it. You should make sure that the hoist can operate without any obstacles or interferences.

Related Product Categories

Winches are mechanical devices consisting of rotating drums, powered manually or electrically, which produce drawing forces on cables for hauling or pulling.

Slings enable you to hoist, move, and position heavy loads safely and efficiently.

Gantry motion-centric system designed for multi-axis operation with an overhead bridge.

Lifting Gears designed to lift large loads and heavy objects.

For further insights or to discuss your unique requirements, we invite you to connect with us Explore the unparalleled expertise and quality solutions that Shabbir Enterprises brings to the table, ensuring your lifting needs are met with precision and reliability.