Product categories

- Material Handling Equipment(63)

- Pallet Trucks(15)

- Forklift(2)

- Mechanical Duct Lifter(1)

- Stackers(10)

- Order Picker(1)

- Platform Lifts(4)

- Hydraulic Scissor Lifting Table(1)

- Drum Grab & Drum Trolley(4)

- Trolleys & Carts(7)

- Prestar Trolley(18)

- Lifting Equipment(39)

- Clamps(6)

- Beam Clamp(1)

- Horizontal Clamp(1)

- Pipe Lifting Clamp(2)

- Vertical Clamp(2)

- Hoist(7)

- Trolley(2)

- Geared Trolley(1)

- Plain Trolley(1)

- Winch(5)

- Drum Lifter(4)

- Lifmex(4)

- Digital Crane Scale(1)

- Gantry(1)

- Mechanical Jack(1)

- Spring Balancer(1)

- Permanent Magnet Lifter(1)

- Hand Puller(1)

- Electric Wire Rope Hoist(1)

- Mini Electric Wire Rope Hoist(1)

- Ratchet Puller(1)

- Tirfor(1)

- Wire Rope Grip(1)

- Other Products(4)

- Clamps(6)

- Rigging Equipment(52)

- Shackle(4)

- Hooks & Accessories(22)

- Snatch Blocks(2)

- Gin Wheel Block(2)

- Commercial Snatch Block(3)

- Load Binder(2)

- Chain(3)

- Wire Rope(4)

- Turnbuckle(1)

- Comercial & Other Rigging Accesories(8)

- Pressing Machine(1)

- Safety Equipment(40)

- Fire Protection Equipment(1)

- FORKED LANYARDS(1)

- Lifting Slings(4)

- Accessories(12)

- Fall Arrester(4)

- Fire blanket(1)

- Safety harnesses(5)

- Nets(2)

- Ropes(6)

- Tarpaulin(3)

- Tent(1)

- Ladders(10)

- Aluminium(4)

- Fibreglass(3)

- Rope(1)

- Scaffolding(1)

- Domestic Ladder(1)

Material Handling Equipment Suppliers in UAE

-

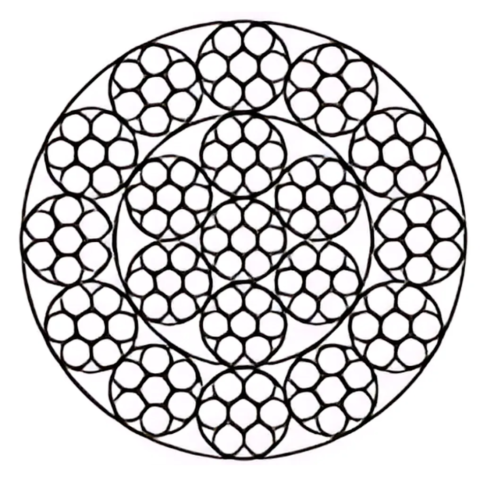

Pvc Coated Wire Rope

PVC Coated

Main Applications: Widely used in automobiles, ship building, construction industry and all needs of outdoor applications or special working environment.

Mainly used in mine hoist cage, meat processing plant, upgrade machinery, ship anchors and fishing operations, fishing vessels trawling.

-

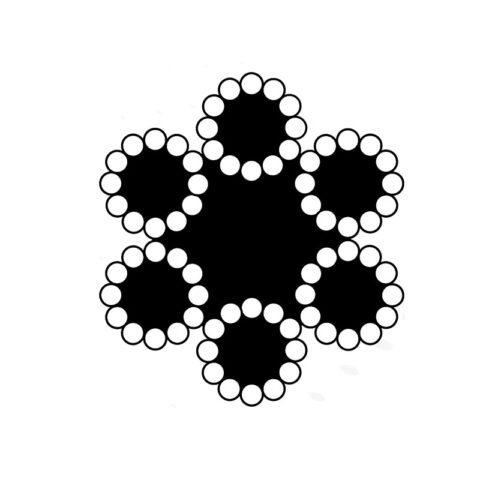

Steel Core Wire Rope

Galvanized vs. Ungalvanized Wire Rope

- Wire Rope is a critical component in many industries, from construction and mining to marine and agriculture. Two common types are galvanized and ungalvanized wire ropes.

Galvanized Wire Rope

- Galvanized Wire Rope is made by coating steel wire with a layer of zinc through a process called galvanization. This protective zinc coating significantly enhances the rope’s resistance to corrosion, making it ideal for outdoor and harsh environment applications.

Looking For Steel Wire Rope Suppliers In UAE? Shabbir Enterprises Is Where You Should Be!

If you are on the lookout for a steel wire rope manufacturer and supplier with an excellent market reputation in the UAE, then your search has come to an end at Shabbir Enterprises. Since our inception in 1984, we have continually offered an outstanding product line of world-class steel wire ropes to our clients based in Dubai and across the United Arab Emirates.

One Of The Trusted Steel Wire Rope Suppliers In Dubai

Used most commonly in the construction industry, steel wire ropes are pieces of mechanical machinery with several properties and specifications that impact their performance and life. Meant to support and move objects and loads, these are attached to cranes or hoists along with shackles and swivels to attach to and move load in a controlled manner.

The wire ropes provided by Shabbir Enterprises are the preferred lifting equipment for several reasons, including their strength, flexibility, corrosion resistance and so much more. What truly sets us apart is that every single product that we deliver to our clients’ doorstep is manufactured following international standards and guidelines.

We Are Here To Listen To You

We believe that a one-size-fits-all approach simply cannot work within our sector. This is why we make ourselves available at all times to listen to you and then suggest products that best match your individual requirements.. We also immensely interest ourselves in any suggestions sent in by our clients, as we believe that they will help us enhance our product quality and services in general.

Contact Us Today

For further details about our products or to send in your suggestions, please give us a call at +971 4 2225401 and +971 505601914. You can also email us at inquiry@shabbirenterprises.com or fill in our enquiry form and we will get back to you as soon as possible.

know more about us

Discover more about Shabbir Enterprises by downloading our comprehensive company profile. Learn about our history, core services, milestones, and how we continue to drive innovation in the industry. Get a deeper understanding of our commitment to excellence and how we can serve your business needs.

our customers LOVE US