1. What is Wire Rope?

Wire rope, also known as cable or wire cable, is a flexible and strong construction made by twisting individual steel wires together. It consists of a central core (usually fiber or steel) surrounded by multiple strands, which in turn contain several wires. Wire ropes are commonly used for lifting, rigging, and other heavy-duty applications due to their high strength and durability”

2. Can Wire Rope Be Welded?

Welding wire rope is generally not recommended due to potential damage to the wires and strands. Heat from welding can weaken the steel, affecting its load-bearing capacity. Instead, mechanical splicing or using specialized connectors is preferred for joining wire ropes.

3. Can Wire Rope Be Cut?

Yes, wire rope can be cut using appropriate tools such as wire rope cutters or abrasive wheels. However, care must be taken to prevent fraying or unraveling of the wires during the cutting process.

4. Can Wire Rope Be Recycled?

Yes, indeed, wire rope can be recycled. The steel wires, which are, in fact, valuable scrap material, can be melted down for reuse. It is crucial to follow proper disposal and recycling practices to effectively minimize environmental impact.

5. How Is Wire Rope Made?

Wire rope manufacturing involves twisting individual wires into strands, which are then helically wound around a core. The process varies based on the type of wire rope (e.g., rotation-resistant, galvanized, or stainless steel). Lubrication and heat treatment enhance durability.

6. How to Wire Rope Clamp?

- Wire rope clamps (also called wire rope clips) are used to secure the ends of wire ropes. Follow these steps:

-

-

- Place the clamp over the rope.

- Tighten the nuts evenly.

- Ensure proper spacing between clamps.

- Inspect for secure attachment.

-

7. What Is Wire Rope Lay?

Wire rope lay refers to the direction in which the wires and strands are twisted during manufacturing. Common types include regular lay (wires and strands twist in the same direction) and Lang lay (opposite twisting directions). Lay affects flexibility and strength.

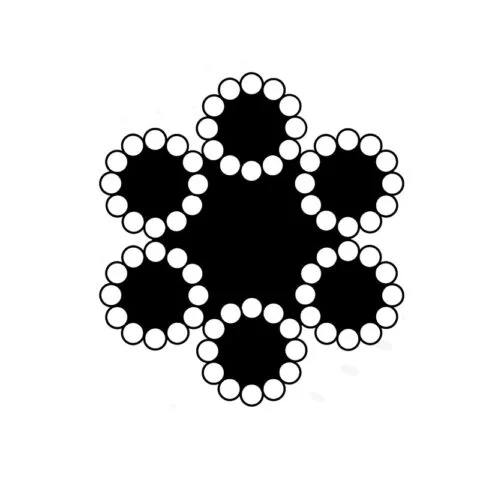

8. What Is Wire Rope Construction?

Wire rope construction refers to the arrangement of wires and strands, encompassing common constructions such as 6×19 (comprising 6 strands with 19 wires per strand), 7×7, and 6×37. Notably, each construction possesses specific properties related to flexibility, strength, and resistance to abrasion, which are essential considerations for various applications.

9. When Is Wire Rope Used as a Guardrail System?

Wire rope guardrails are commonly used in industrial settings, construction sites, and bridges. Furthermore, they provide fall protection, boundary delineation, and safety barriers. It’s imperative to note that proper installation and regular inspection are crucial for their effectiveness, ensuring continued safety and reliability.

10. Where Is Wire Rope in Home Depot?

At Home Depot, wire ropes are typically found in the hardware and construction materials section. You can easily spot them near chains, cables, and other rigging supplies. Keep an eye out for these essentials while browsing for your project needs.

11. Which Wire Rope Is More Flexible?

Generally, wire ropes with a higher number of smaller-diameter wires (e.g., 7×19 construction) are more flexible. Rotation-resistant ropes (e.g., 19×7) are less flexible but offer better load stability.

12. Will Galvanized Wire Rope Rust?

Galvanized wire rope is coated with zinc to resist corrosion. However, over time, the zinc layer may wear off, exposing the steel

13. What Is a Wire Rope Sling?

A wire rope sling, a versatile and robust lifting device, is crafted from tightly braided wire ropes. These slings find extensive use in heavy lifting applications, showcasing remarkable load-bearing capabilities. Essentially, they comprise multiple strands of steel wire meticulously twisted together, resulting in a sturdy and flexible sling.

14. Wire Rope Sling Capacity?

- The rated capacity of a wire rope sling depends on several factors:

-

- Minimum Breaking Force (MBF):

- The Minimum Breaking Force (MBF) of a wire rope is a crucial parameter. It represents the maximum load the rope can withstand before breaking. In other words, it’s the ultimate strength of the rope.

- When selecting a wire rope for lifting applications, ensuring that the MBF exceeds the expected loads is essential. This ensures safety and reliability during lifting operations.

- Design Factor:

- The design factor plays a pivotal role in wire rope safety. It’s a ratio that relates the minimum breaking force of the rope to the total load it is expected to carry.

- According to ASME B30.9 standards, the typical design factor is 5. This means that the MBF of the wire rope should be at least five times the load imposed on it during lifting.

- By adhering to this design factor, we ensure that the wire rope has sufficient capacity to handle dynamic loads, shocks, and other stress factors while maintaining safety.

- Other factors affecting overall strength, such as splicing efficiency.

- Minimum Breaking Force (MBF):

- The capacities are calculated based on the type of hitch (e.g., vertical, choker, or basket) and the diameter of pins or natural eye width. Horizontal sling angles less than 30 degrees should not be used.

-

If you have any specific requirements or need further insights, feel free to discuss them with me. I’m here to assist we invite you to connect with us Explore the unparalleled expertise and quality solutions that Shabbir Enterprises brings to the table, ensuring your material handling equipment’s needs are met with precision and reliability.