Product categories

- Material Handling Equipment(63)

- Pallet Trucks(15)

- Forklift(2)

- Duct Lifter(1)

- Stackers(10)

- Order Picker(1)

- Platform Lifts(4)

- Lifting Table(1)

- Drum Lifter(4)

- Trolleys & Carts(7)

- Prestar Trolley(18)

- Lifting Equipment(40)

- Garage Equipment(4)

- Mechanical Jack(1)

- Pipe Bender(1)

- Shop Crane(1)

- Spring Balancer(1)

- Magnet Lifter(1)

- Manual Puller(3)

- Hand Puller(1)

- Hand Winch(2)

- Tensioning Equipment(3)

- Ratchet Puller(1)

- Tirfor(1)

- Wire Rope Grip(1)

- Clamps(10)

- Hoist(6)

- Chain Hoist Trolley(2)

- Geared Trolley(1)

- Plain Trolley(1)

- Winches(8)

- Crane Scale(1)

- Gantry(1)

- Gantry Crane(1)

- Other Products(2)

- Garage Equipment(4)

- Rigging Equipment(51)

- Commercial Rigging Items(4)

- Commercial Pulley(3)

- Commercial Shackles(1)

- Gin Block(2)

- Load Binder(2)

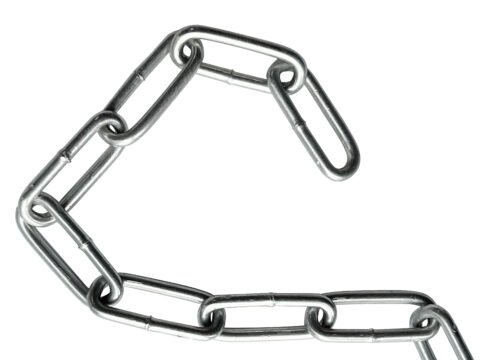

- Chains(3)

- G70 Clevis Grab Hook(1)

- G80 Components(21)

- Wire Rope Cutter(1)

- Shackle(4)

- Hooks & Accessories(21)

- Snatch Blocks(2)

- Commercial Snatch Block(3)

- Wire Rope(4)

- Turnbuckle(1)

- Comercial & Other Rigging Accesories(6)

- Pressing Machine(1)

- Commercial Rigging Items(4)

- Safety Equipment(40)

- Fall Protection Equipment(13)

- Climbing Ropes(2)

- Fall Arrester Block(1)

- Hooks(5)

- Rope Grab(2)

- Safety Belt(2)

- Tripod(1)

- Marine Handling Products(6)

- Protection Equipment(4)

- FORKED LANYARDS(1)

- Lifting Slings(4)

- Accessories(5)

- Fire blanket(1)

- Safety harnesses(5)

- Tarpaulin(1)

- Ladders(10)

- Aluminium(4)

- Fibreglass(3)

- Rope(1)

- Scaffolding(1)

- Domestic Ladder(1)

- Fall Protection Equipment(13)

Material Handling Equipment Suppliers in UAE

-

Din6899 Wire Rope Thimble

- A DIN 6899 Wire Rope Thimble is a type of metal fitting used to protect the end of a wire rope from fraying and to provide a secure attachment point for hooks, shackles, or other rigging hardware. It’s designed to the specifications of the German standard DIN 6899, ensuring quality and safety.

-

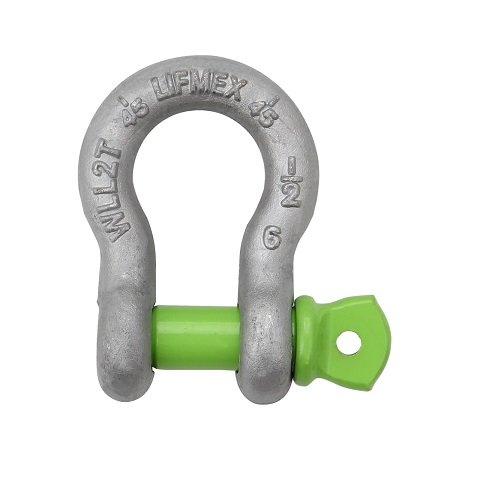

G209 US TYPE FORGED SCREW PIN ANCHOR SHA

The G209 US Type Forged Screw Pin Anchor Typeis a versatile and easy-to-use connector for lifting, rigging, and towing applications. Its wide bow shape allows for multi-directional loading, while the screw pin ensures quick installation and removal—perfect for temporary or adjustable setups.

-

G2130 US TYPE FORGED BOLT TYPE SHACKLE

The G2130 US TYPE FORGED BOLT TYPEis engineered for secure and long-term lifting and rigging applications. Its wide bow design allows for multiple sling connections, while the bolt and nut system ensures maximum safety and stability under heavy loads and dynamic conditions.

-

G2150 US Type Forged Bolt Type Shackle

TheG2150 US Type Forged Bolt Typeis designed for heavy-duty and permanent lifting or rigging applications. Featuring a secure bolt and nut locking system, it offers enhanced safety and resistance against accidental release under load. Ideal for critical applications where vibration or dynamic movement is present.

-

G80 Clevis Belt Hook

A G80 Clevis Belt Hook is a specialized rigging hardware component designed to connect webbing slings to other lifting components, such as chains or other hooks. The “G80” designation indicates that the hook is made from high-quality alloy steel that meets specific strength and durability standards.

-

G80 Clevis Self-locking Hook with Grip

- A G80 Clevis Self Locking Hook with Grip is a specialized lifting component designed to securely hold and lift heavy loads, incorporating additional features to enhance its grip and safety.

- IG80 Clevis Self Locking Hooks with Grip are essential tools for safe and efficient lifting operations, especially in situations where a secure grip on the load is critical. Their self-locking mechanism, high-strength construction, and additional grip features make them a reliable choice for a wide range of applications.

-

G80 Clevis Shortening Grab Hook

- A G80 Clevis Shortening Grab Hook is a specialized rigging hardware component designed to shorten the length of a chain sling without compromising its load-bearing capacity.

- It’s primarily used in lifting applications where precise adjustments to the sling length are required.

-

G80 Omega Link

- G80 Omega Links are primarily used in lifting and rigging applications to connect different components of a lifting assembly. Here are some specific uses:

- Connecting Chain Slings: They are used to connect chain segments or attach end fittings to chain slings.

- Creating Custom Lifting Configurations: They are employed to create custom lifting configurations for specific tasks, such as lifting irregular or oddly shaped loads.

- Rigging Equipment: They are utilized in various rigging setups to secure loads and components.

- In essence, G80 Omega Links provide a reliable and secure connection between different components of a lifting assembly, ensuring safe and efficient material handling.

-

G80 Welded Master Link with Flat Master

- A G80 Welded Master Link with Flat Master Link is a specialized lifting component designed to connect multiple chains or slings into a single assembly.

- It’s particularly useful for creating custom lifting configurations to accommodate various load shapes and sizes.

-

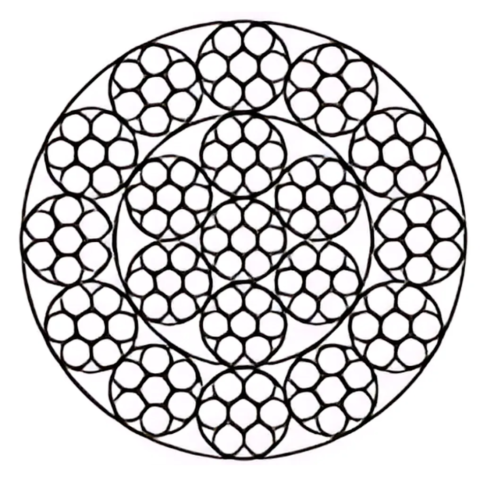

Pvc Coated Wire Rope

PVC Coated

Main Applications: Widely used in automobiles, ship building, construction industry and all needs of outdoor applications or special working environment.

Mainly used in mine hoist cage, meat processing plant, upgrade machinery, ship anchors and fishing operations, fishing vessels trawling.

Rigging Equipment Suppliers UAE

know more about us

Discover more about Shabbir Enterprises by downloading our comprehensive company profile. Learn about our history, core services, milestones, and how we continue to drive innovation in the industry. Get a deeper understanding of our commitment to excellence and how we can serve your business needs.