Product categories

- Material Handling Equipment(63)

- Pallet Trucks(15)

- Forklift(2)

- Duct Lifter(1)

- Stackers(10)

- Order Picker(1)

- Platform Lifts(4)

- Lifting Table(1)

- Drum Lifter(4)

- Trolleys & Carts(7)

- Prestar Trolley(18)

- Lifting Equipment(40)

- Garage Equipment(4)

- Mechanical Jack(1)

- Pipe Bender(1)

- Shop Crane(1)

- Spring Balancer(1)

- Magnet Lifter(1)

- Manual Puller(3)

- Hand Puller(1)

- Hand Winch(2)

- Tensioning Equipment(3)

- Ratchet Puller(1)

- Tirfor(1)

- Wire Rope Grip(1)

- Clamps(10)

- Hoist(6)

- Chain Hoist Trolley(2)

- Geared Trolley(1)

- Plain Trolley(1)

- Winches(8)

- Crane Scale(1)

- Gantry(1)

- Gantry Crane(1)

- Other Products(2)

- Garage Equipment(4)

- Rigging Equipment(51)

- Commercial Rigging Items(4)

- Commercial Pulley(3)

- Commercial Shackles(1)

- Gin Block(2)

- Load Binder(2)

- Chains(3)

- G70 Clevis Grab Hook(1)

- G80 Components(21)

- Wire Rope Cutter(1)

- Shackle(4)

- Hooks & Accessories(21)

- Snatch Blocks(2)

- Commercial Snatch Block(3)

- Wire Rope(4)

- Turnbuckle(1)

- Comercial & Other Rigging Accesories(6)

- Pressing Machine(1)

- Commercial Rigging Items(4)

- Safety Equipment(40)

- Fall Protection Equipment(13)

- Climbing Ropes(2)

- Fall Arrester Block(1)

- Hooks(5)

- Rope Grab(2)

- Safety Belt(2)

- Tripod(1)

- Marine Handling Products(6)

- Protection Equipment(4)

- FORKED LANYARDS(1)

- Lifting Slings(4)

- Accessories(5)

- Fire blanket(1)

- Safety harnesses(5)

- Tarpaulin(1)

- Ladders(10)

- Aluminium(4)

- Fibreglass(3)

- Rope(1)

- Scaffolding(1)

- Domestic Ladder(1)

- Fall Protection Equipment(13)

Material Handling Equipment Suppliers in UAE

51Products found

Filter

-

G80 European Type Clevis Self-locking Ho

- A G80 Clevis Self Locking Hook is a specialized lifting component designed to securely hold and lift heavy loads. It’s characterized by its clevis (U-shaped) design and a self-locking mechanism that prevents accidental release.

- G80 Clevis Self Locking Hooks are essential tools for safe and efficient lifting operations. Their self-locking mechanism, high-strength construction, and compliance with safety standards make them a reliable choice for a wide range of applications

-

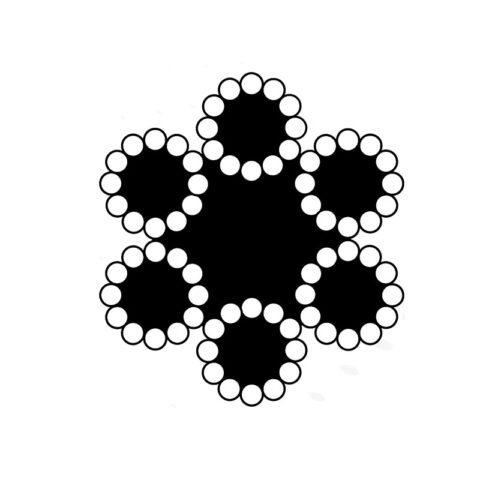

Steel Core Wire Rope

Galvanized vs. Ungalvanized Wire Rope

- Wire Rope is a critical component in many industries, from construction and mining to marine and agriculture. Two common types are galvanized and ungalvanized wire ropes.

Galvanized Wire Rope

- Galvanized Wire Rope is made by coating steel wire with a layer of zinc through a process called galvanization. This protective zinc coating significantly enhances the rope’s resistance to corrosion, making it ideal for outdoor and harsh environment applications.

-

G80 European Type Eye Self-locking Hook

- A G80 Eye Self Locking Hook is a specialized lifting component designed to securely hold and lift heavy loads. It’s characterized by its eye-shaped design and a self-locking mechanism that prevents accidental release.

- G80 Eye Self Locking Hooks are essential tools for safe and efficient lifting operations. Their self-locking mechanism, high-strength construction, and compliance with safety standards make them a reliable choice for a wide range of applications.

-

Lever Type Load Binder

- A Load Binder Lever Type is a mechanical device used to secure and tighten heavy loads, such as chains, ropes, or straps. It provides a quick and efficient way to apply tension and prevent slippage.

- While Lever-type Binders are easier to operate than Ratchet-type Binders, they may not provide as much tensioning force.

Rigging Equipment Suppliers UAE

know more about us

Discover more about Shabbir Enterprises by downloading our comprehensive company profile. Learn about our history, core services, milestones, and how we continue to drive innovation in the industry. Get a deeper understanding of our commitment to excellence and how we can serve your business needs.